The Evolution of Cattle Head Gates

How Cattle Head Gates Have Evolved to Improve Safety and Handling

Go Back to All BlogsPosted on: November 21, 2025

Updated on: November 25, 2025

Author: Janelle Hulme

SHARE:

Since the first cattle head gates were invented, the industry has come a long way. Early head gates were mounted to fence posts and built from whatever materials a rancher had on hand. Today, head gates are engineered with animal behavior, handler safety, and low-stress cattle handling in mind.

The purpose of a head gate is simple: secure the animal safely during health checks, treatments, tagging, or any necessary procedure. How head gates have evolved matters, because better design leads to safer, more efficient handling for cattle and handlers.

Different head gate styles - self-catch and manual catch - play a major role in how smoothly your operation runs.

Self-Catch Head Gates

Over the years, head gates shifted from manual adjustments to automatic or self-catch systems. A self-catch (or auto-adjusting) head gate works by having the animal “catch themselves” as their shoulders activate the closing mechanism. After each use, the head gate must be reset, and often the opening needs to be adjusted for cattle of different sizes.

Self-catch head gates are usually more affordable, making them appealing for some ranchers. However, research shows they can be harder on cattle and harder to use. Cattle may become wary of entering after a few runs, and the force of the mechanism can increase stress and cause bruising. Frequent size adjustments also slow down work, and on any ranch, time is money.

Manual Head Gates

Manual head gates are proven to lower stress by aligning more closely with cattle psychology and behavior. That’s why Arrowquip transitioned away from self-catch designs and now manufactures chutes with manual head gates, as they’re proven to be safer, quieter, and more efficient.

Arrowquip’s patented Direct Drive system provides rapid response in the 3E Head Gate, helping reduce missed catches. By controlling the catch, stress and shoulder bruising are both minimized. The 3E (Easy Entry & Exit) design uses light to guide cattle forward naturally, supporting smooth flow and calmer animals. Once inside the chute, quieter operation further reduces stress.

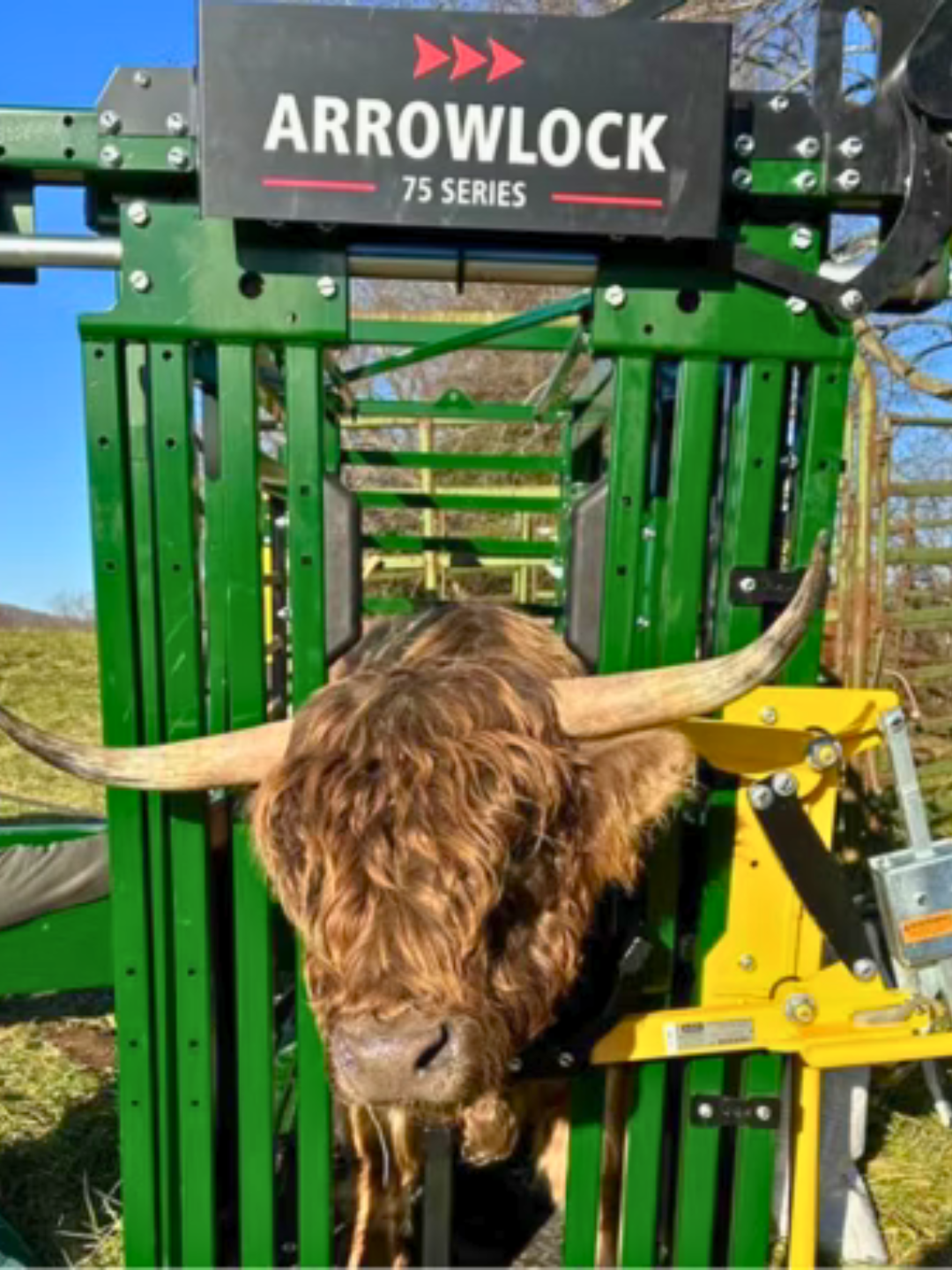

Arrowquip’s new Arrowlock manual head gate features a ratchet-and-pawl locking system that provides up to 8× more holding force, giving ranchers secure control without excessive pressure.

Choosing the Right Head Gate

When selecting a head gate, focus on:

Low-stress cattle handling

User-friendly operation

Safe, quiet movement

Reliable control and consistent holds

Durability and long-term value

A good head gate improves efficiency, protects cattle, and supports the kind of handling that pays off at sale time.

The evolution of the cattle head gate reflects how far the livestock industry has come, with better tools, better science, and better outcomes for ranchers and their herds.