Design Tips for Safer Cattle Handling Systems

How Good Design Improves Safety and Efficiency in Cattle Handling

Go Back to All BlogsPosted on: April 3, 2025

Updated on: October 22, 2025

Author: Liane Carter

SHARE:

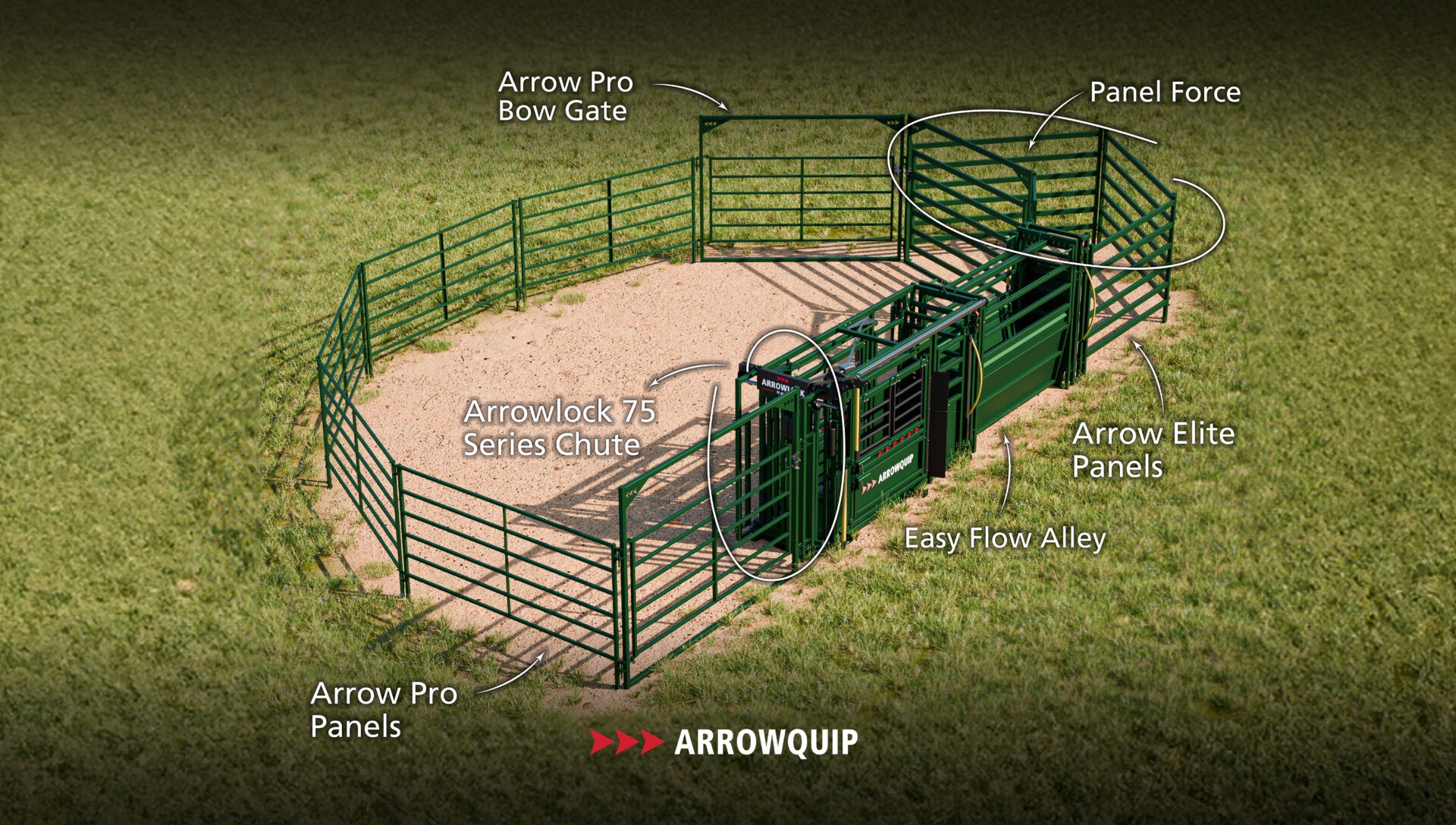

Cattle handling systems should be designed with handler and livestock safety kept top of mind. If you currently dread the time and effort it takes to work cattle with your system, it may be time to consider upgrading.

By making a few changes, you can help alleviate your biggest pain points. Some changes may include upgrading your squeeze chute, adding new corral panels, or changing the layout to increase cattle flow. These changes can turn your cattle handling experience into something you enjoy again in no time.

Designing Your System

When designing your cattle handling system, the first step is selecting the area where you’ll set it up. The location of your system can affect how cattle flow through it and may dictate how you can change it in the future. When selecting the area to build your system, it’s important to consider accessibility, drainage, fencing, and electricity available to operate hydraulics.

You’ll also want to think about your current cattle handling needs and the future growth of your operation when designing your cattle handling system. If you plan to expand in the coming years, it’s better to design a larger cattle handling system now, rather than renovating an outdated system later, or risk injuries from attempting to work cattle in an overcrowded area. If you choose to design a larger system for the future of your operation, keep in mind that cattle can easily evade handlers in large pens. Gates and additional panels can be used to easily adjust pen sizes as your operation changes and grows. Plan for 20 square feet per cow and 14 square feet per calf in your holding pen designs.

Design Recommendations

Now the time has come to design the cattle handling system of your dreams. Here are some design recommendations you should keep in mind during the process:

Plan for Handler Safety. Always define a clear escape route in case something goes wrong and you need to get out of the pen as quickly as possible. Using panels with built-in man gates ensures you can get out quickly if needed, without cattle escaping. Also, be sure to dedicate a cattle-free area and consider adding access gates at key points throughout the system to avoid having to climb over panels.

Choose Safe and Efficient Equipment. Corral panels and gates with wide rectangular rail designs allow cattle to see outside of the system while decreasing the chances of them challenging. This minimizes the likelihood of unsafe situations and injuries. For the safety of your cattle, ensure that equipment such as the alleys and cattle chutes have emergency exit options in case of an emergency that requires the animal to escape quickly.

Optimize Cattle Alley Design. Keep the cattle alley straight at the entrance and exit of a Bud Box or cattle tub. The minimum length should be approximately 12-feet and the alleys should be wide enough for cattle to move forward, but not so wide they can turn around. Selecting an alley with adjustable sides is recommended to ensure your cattle flow seamlessly.

Surface and Traction Matter. Cattle will be safer and calmer on surfaces that provide good traction, minimizing slips and falls. If you have a chute with your system, always remember that rubber flooring reduces noise, which will reduce stress on cattle. Throughout your handling system, keep in mind that packed dirt and gravel help prevent slips.

Leverage Natural Behavior. Cattle prefer moving uphill, in curves, and toward light. Incorporate these design elements into your system to encourage low-stress movement. The equipment you use should also work with cattle behavior – such as cattle chutes that incorporate light and complete cattle access into their designs.

Electrical Safety. If you’re using electricity for hydraulics or other equipment, install moisture-proof, ground fault outlets to protect both yourself and your cattle.

By following these recommendations and working with a cattle handling system design expert, you can be sure that you have the safest, most efficient cattle handling system of your dreams. Talk with one of Arrowquip’s experts today to get started.